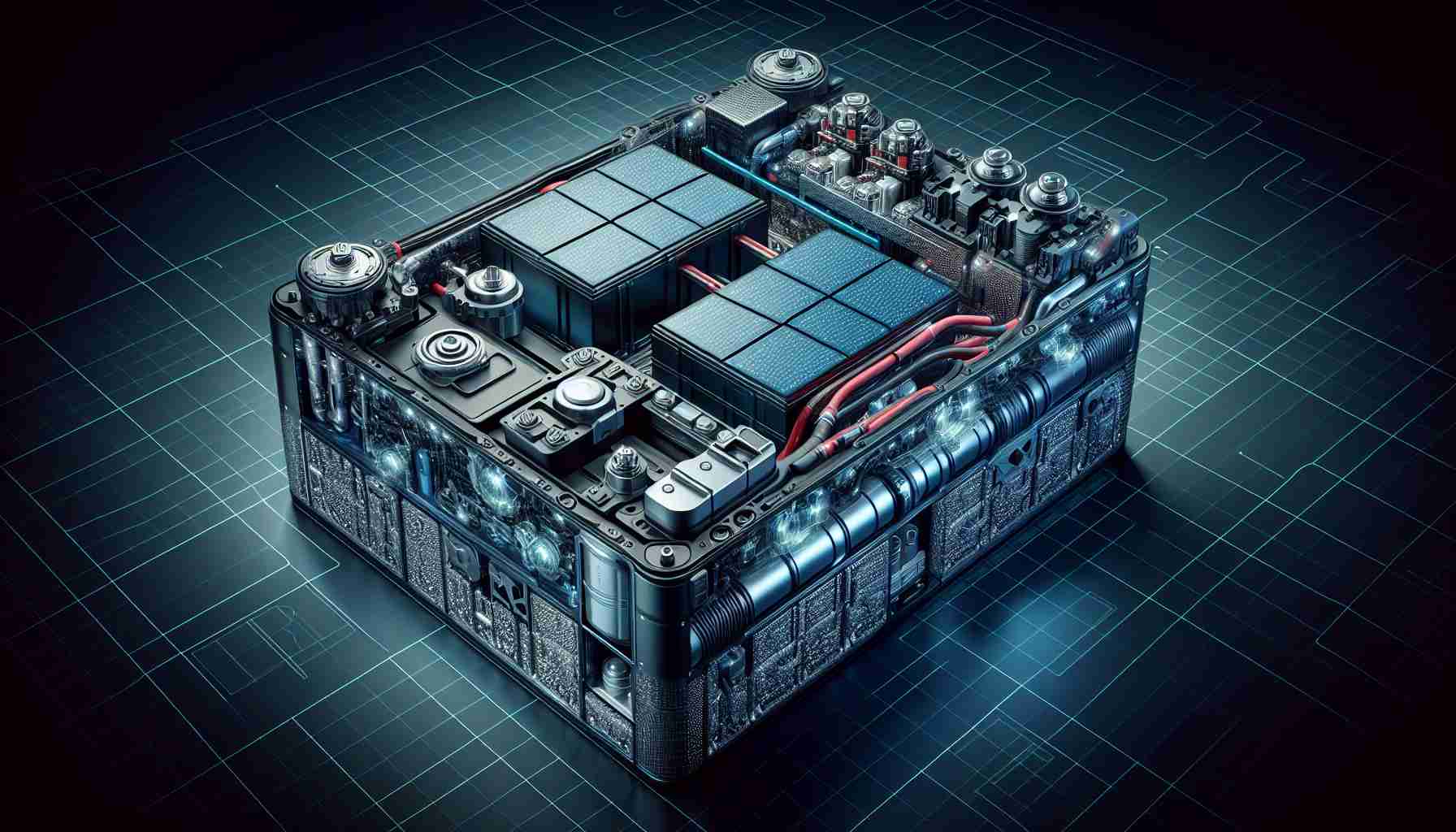

General Motors (GM) has unveiled a groundbreaking shift in its electric vehicle battery strategy by introducing a new battery technology that promises a significant cost reduction while maintaining efficiency. The company has decided to bid goodbye to the Ultium battery brand name, opting instead to integrate lithium iron phosphate (LFP) batteries into its electric vehicles.

Unlike the traditional nickel cobalt manganese (NCM) batteries commonly used in the automotive industry, LFP batteries offer a more cost-effective solution with simplified production processes. With a potential cost reduction of up to $6,000 per vehicle, GM aims to make electric vehicles more accessible to the masses.

This strategic move aligns with GM’s commitment to environmental sustainability by reducing dependency on cobalt, often referred to as the “blood diamond of batteries.” By adopting LFP technology, GM joins the ranks of other industry players like Tesla and Ford, leading the charge towards cleaner and more affordable electric transportation.

In addition to enhancing its battery technology, GM plans to establish a state-of-the-art battery cell development center in Warren, Michigan, to compete with global battery manufacturers effectively. The company’s investment in battery innovation reflects its dedication to meeting the growing demand for electric vehicles in the market.

By leveraging the cost-efficient LFP batteries and streamlining its battery pack design, GM anticipates further reductions in production costs and an extended driving range for its electric vehicle lineup. This strategic shift underscores GM’s commitment to driving innovation and sustainability in the electric vehicle industry.

GM Expands Commitment to Electric Vehicle Batteries with Cutting-Edge Innovations

General Motors (GM) continues to make waves in the electric vehicle market by unveiling new advancements in battery technology that go beyond just cost reduction. Building on its recent shift to lithium iron phosphate (LFP) batteries, GM is now focusing on maximizing energy density and longevity in its electric vehicles.

What are the key advancements in GM’s latest innovation?

GM’s new battery technology not only promises a significant cost reduction but also boasts higher energy density than traditional batteries, resulting in increased driving range per charge. Additionally, the longevity of these batteries is expected to surpass current industry standards, providing a more sustainable and long-term solution for electric vehicle owners.

What are the main challenges or controversies associated with these advancements?

One of the key challenges is ensuring that these advanced batteries undergo rigorous testing to guarantee safety and reliability over the long term. Additionally, questions may arise regarding the scalability of production to meet the increasing demand for electric vehicles globally. Balancing the push for innovation with the need for practicality and efficiency remains a crucial challenge for GM and other automakers.

Advantages and Disadvantages of GM’s Latest Battery Innovation:

Advantages:

– Increased energy density for extended driving range

– Enhanced longevity compared to traditional batteries

– Cost reduction making electric vehicles more accessible

– Environmental sustainability by reducing cobalt dependency

Disadvantages:

– Initial investment in new technology may be high

– Potential challenges in scaling up production

– Continuous research and development needed to stay competitive

As GM propels the electric vehicle industry forward with its cutting-edge battery technology, the company aims to solidify its position as a leader in sustainable transportation solutions.

For more insights on electric vehicle innovation and trends, visit GM’s official website at GM Official Website.