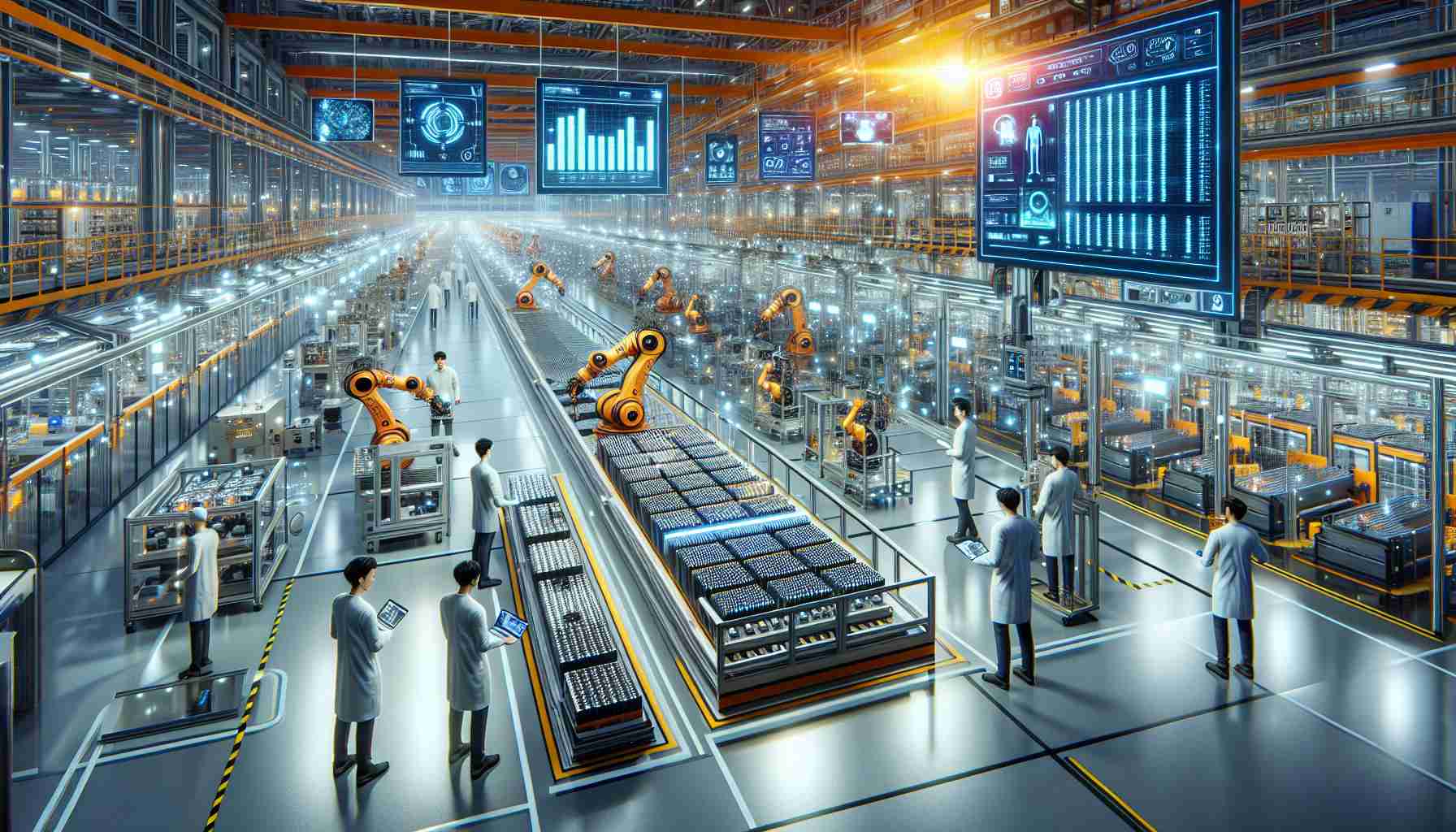

Inspecting the internal structure of batteries has never been more crucial in the rapidly evolving landscape of energy production and storage. Cutting-edge inspection technologies are transforming the way manufacturers ensure quality and safety while keeping up with the increasing demand for high-performance batteries.

Utilizing advanced nondestructive testing (NDT) solutions, manufacturers can now detect defects early in the production process, reducing the likelihood of recalls and improving overall product reliability. Technologies such as industrial X-ray and computed tomography (CT) provide detailed insights into the internal components of battery cells, facilitating the identification of critical issues like misaligned electrodes, cracks, and cavities without damaging the original parts.

Integration of X-ray and CT inspections not only streamlines the quality control process but also paves the way for optimizing production processes. Automated measurements and reports generated by intelligent software and AI tools enhance efficiency, freeing up inspectors’ time for more strategic tasks.

Furthermore, these inspection technologies contribute to cost efficiency and environmental sustainability by minimizing material waste and reducing the impact of defective products on the environment. By detecting and rectifying defects early on, manufacturers can enhance the lifespan and performance of batteries, ultimately supporting the transition towards a more sustainable energy ecosystem.

Embracing cutting-edge inspection technologies is not only a strategic move for manufacturers aiming to meet the demands of the future but also a critical step towards ensuring the safety, reliability, and efficiency of next-generation battery solutions.

Exploring Next-Level Innovations in Battery Production through Advanced Inspection Techniques

In the realm of revolutionizing battery production, there are several key questions that arise when delving into the adoption of cutting-edge inspection technologies. Here are some of the most important queries along with insightful answers to provide a comprehensive understanding of this transformative field:

1. How do emerging inspection technologies address the evolving needs of the battery industry?

Advanced inspection technologies go beyond traditional methods by offering enhanced capabilities to detect even the most minute defects in battery components. This proactive approach enables manufacturers to preemptively address issues, thereby ensuring superior quality and performance in the final products.

2. What are the primary challenges associated with implementing cutting-edge inspection solutions in battery production?

One of the major challenges lies in the initial investment required for acquiring and integrating advanced inspection tools into existing manufacturing processes. Additionally, there may be a learning curve for operators to fully utilize the potential of these sophisticated technologies, necessitating comprehensive training programs.

3. Are there any controversies surrounding the use of advanced inspection technologies in battery production?

Some stakeholders may express concerns about the potential dependence on automation and artificial intelligence in the inspection process, raising questions about the role of human expertise and oversight. Balancing the benefits of automation with the necessity of human judgment remains a subject of debate within the industry.

Advantages of leveraging cutting-edge inspection technologies in battery production include:

– Enhanced Quality Control: By enabling early detection of defects, these technologies help maintain high standards of quality throughout the manufacturing process.

– Improved Safety: Identifying issues such as misaligned electrodes or internal cracks enhances the safety of batteries, reducing the risk of malfunctions or failures.

– Increased Efficiency: Automation and intelligent software streamline inspection processes, boosting overall efficiency and productivity in production facilities.

However, there are also certain disadvantages to consider, such as:

– Initial Investment Costs: Acquiring and implementing advanced inspection technologies can entail significant upfront expenses for manufacturers.

– Maintenance and Upkeep: Ensuring the proper functioning of complex inspection equipment requires ongoing maintenance and regular calibration to sustain accuracy.

– Potential Technological Obsolescence: As technology evolves rapidly, there is a risk of newer, more advanced solutions becoming available, potentially rendering current systems outdated.

For further insights into the latest innovations and trends shaping the battery production landscape, explore the resources available on the U.S. Department of Energy’s website. This reputable source offers valuable information on sustainable energy initiatives and technological advancements in the field.