Breaking away from conventional battery materials, Lyten, a Silicon Valley startup, is spearheading a new era in energy storage technology. The recent acquisition of manufacturing assets from Northvolt signifies a pivotal moment in the industry.

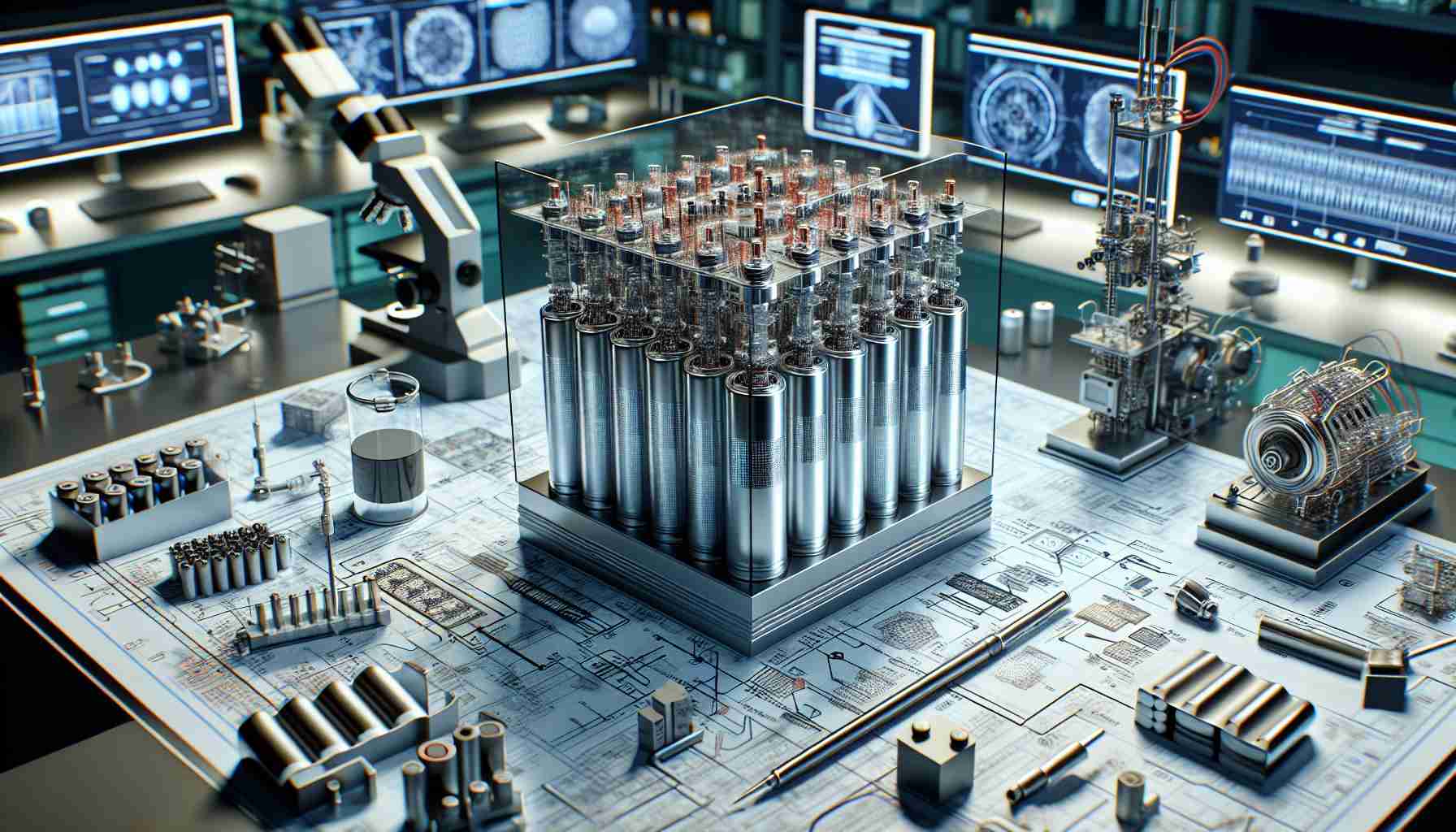

Lyten’s unique strategy involves utilizing sulfur within a graphene matrix for cathode materials, a stark contrast to traditional nickel or cobalt-based components. By steering clear of graphite on the anode side, which is subject to export restrictions, Lyten is able to craft cells with exceptional energy density at a fraction of the production cost.

Unlike its counterpart, Northvolt has faced setbacks in lithium-ion battery production, leading to significant operational challenges. Despite recent cost-cutting measures and partnerships, the company continues to grapple with financial instability.

On the contrary, Lyten is on a trajectory of growth and expansion. With plans for a cutting-edge factory in Nevada capable of producing lithium-sulfur batteries for various applications, including micromobility and aerospace sectors, the startup is set to revolutionize the market by delivering innovative solutions.

By acquiring Northvolt’s assets, Lyten gains a competitive edge, enhancing its capacity to produce lithium-sulfur batteries locally. With substantial investments and strong backing, Lyten is poised to lead the charge in shaping the future of energy storage technologies, setting a new benchmark in the sector.

Expanding Horizons: Lyten’s Continued Innovation in Energy Storage

Amidst the ongoing transformation in battery technology, Lyten’s pioneering approach stands out with its focus on leveraging unconventional yet highly effective materials for energy storage solutions. While the company’s acquisition of manufacturing assets from Northvolt has garnered significant attention, there are other intriguing facets to Lyten’s innovative strategy that deserve exploration.

Key Questions:

1. What sets Lyten’s lithium-sulfur batteries apart from conventional options in terms of performance and sustainability?

2. How does Lyten’s unique use of sulfur within a graphene matrix contribute to enhanced energy density and cost-efficiency?

3. What potential impact could Lyten’s cutting-edge factory in Nevada have on the broader energy storage market?

Crucial Insights:

– One crucial question that arises is whether Lyten’s sulfur-graphene composition poses any environmental or safety concerns that need to be addressed in the long run.

– Another important consideration is how Lyten plans to scale up its production to meet the increasing demand for its innovative battery technology while maintaining quality and consistency.

– Additionally, the compatibility of Lyten’s lithium-sulfur batteries with existing infrastructure and devices is a key aspect that needs to be analyzed for seamless integration and market adoption.

Advantages and Disadvantages:

On one hand, Lyten’s approach offers the potential for significantly higher energy density and lower production costs compared to traditional battery materials, paving the way for more efficient energy storage solutions. However, the use of sulfur may raise concerns about the overall performance and longevity of the batteries over time, as sulfur-based components can be prone to degradation.

Furthermore, while Lyten’s expansion plans and technological advancements signify progress in the energy storage sector, the company may encounter challenges related to regulatory approvals, market acceptance, and competition from established players in the industry.

Related Links:

– Lyten’s Official Website

– National Geographic’s Coverage on Battery Technology Innovations