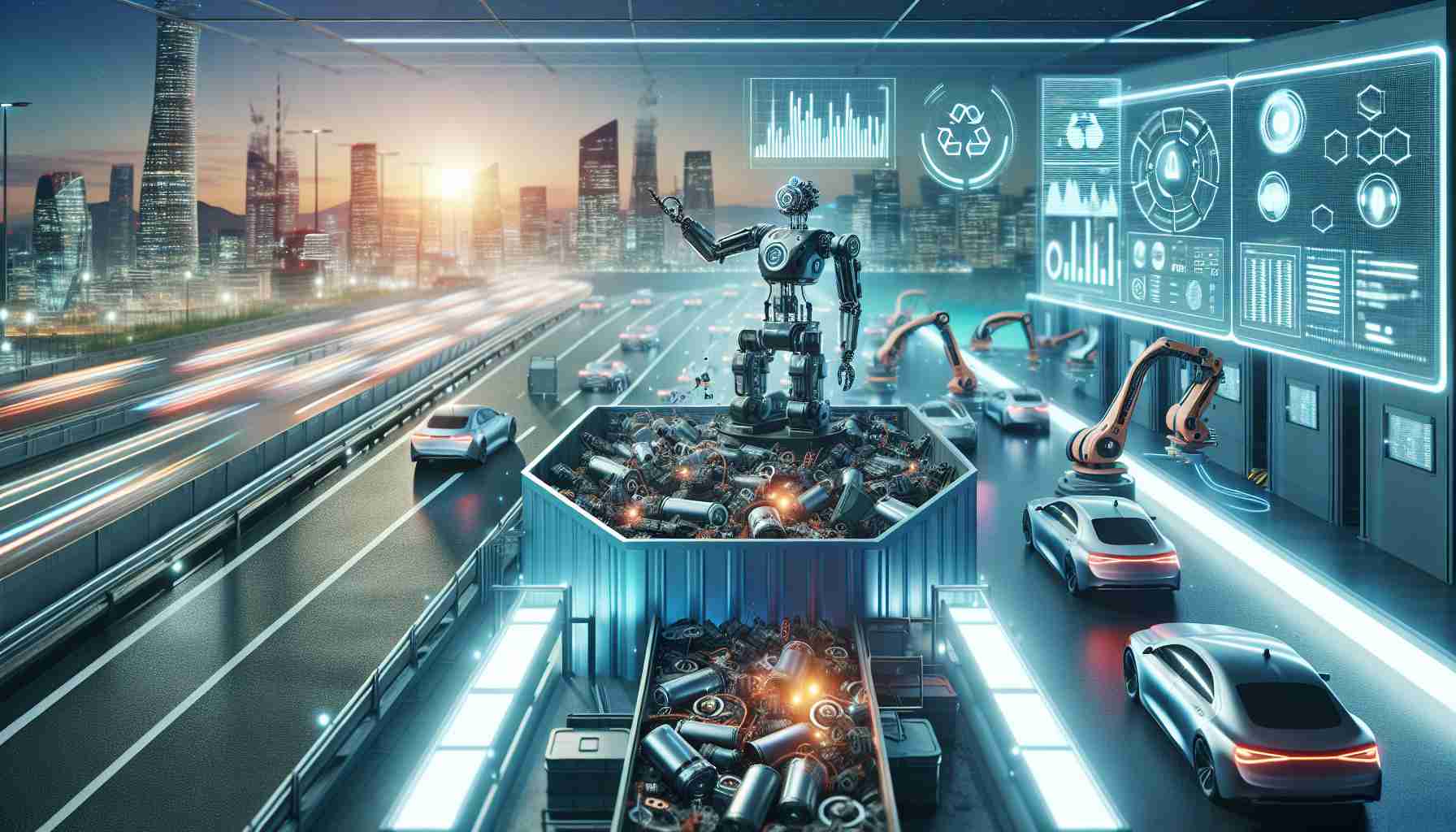

Mercedes-Benz has spearheaded a groundbreaking advancement in the automotive industry with its pioneering battery recycling plant initiative. The company’s state-of-the-art facility in Southern Germany signals a major shift towards sustainability and resource efficiency. Rather than solely relying on external partners, Mercedes-Benz has taken the lead in establishing a closed-loop system for battery recycling, setting a new benchmark in the sector.

Through a cutting-edge mechanical-hydrometallurgical process, Mercedes-Benz aims to significantly reduce energy consumption and waste production compared to traditional methods. Teaming up with technology partner Primobius, the company has developed a comprehensive approach that encompasses all stages of recycling, from shredding battery modules to extracting valuable metals like cobalt, nickel, and lithium.

While EV battery recycling remains a relatively niche segment, its importance is growing exponentially in tandem with the rise of electric vehicles. By embracing innovative recycling practices, automakers can mitigate their environmental impact, reduce dependency on raw material supplies, and pave the way for a more sustainable future.

Mercedes-Benz’s commitment to achieving a 96% recovery rate of raw materials from recycled batteries underscores the immense potential for circularity within the automotive industry. As other major players such as BMW, Volkswagen, and Ford also enter the realm of battery recycling, the transition towards a circular economy for electric vehicle components is well underway. Embracing these innovative approaches will not only revolutionize the automotive industry but also contribute significantly to global sustainability efforts.

Revolutionizing Battery Recycling: Uncovering Key Questions and Challenges

As the automotive industry continues to pivot towards sustainable practices, the spotlight on battery recycling grows brighter. While the previous article touched on Mercedes-Benz’s pioneering efforts in this realm, there are important questions that warrant exploration to understand the broader landscape of innovative approaches to battery recycling.

What are the key challenges associated with battery recycling in the automotive industry?

One of the primary challenges in battery recycling is the complex composition of lithium-ion batteries used in electric vehicles. These batteries contain a mix of valuable metals like cobalt, nickel, and lithium, which are challenging to extract efficiently. Additionally, ensuring the safety and proper handling of battery waste throughout the recycling process is crucial to prevent environmental contamination.

What advantages do innovative approaches to battery recycling offer?

Innovative approaches to battery recycling, such as Mercedes-Benz’s mechanical-hydrometallurgical process, present several advantages. These include reduced energy consumption and waste production, maximization of raw material recovery, and a significant decrease in the environmental footprint of electric vehicles. By adopting such approaches, automakers can establish closed-loop systems that promote sustainability and resource efficiency.

Are there any controversies surrounding battery recycling practices?

While the shift towards battery recycling is generally lauded for its environmental benefits, some controversies exist regarding the environmental impact of extracting raw materials for new batteries. Critics argue that the mining of metals like cobalt and lithium for battery production can have negative consequences on local ecosystems and communities. Balancing the need for recycling with responsible sourcing of raw materials remains a key point of contention in the industry.

In summary, the automotive industry’s venture into innovative battery recycling approaches marks a crucial step towards a more sustainable future. Addressing key questions, challenges, and controversies associated with this topic will be instrumental in shaping the trajectory of environmental stewardship within the sector.

For further insights and information on sustainable practices in the automotive industry, visit Union of Concerned Scientists.