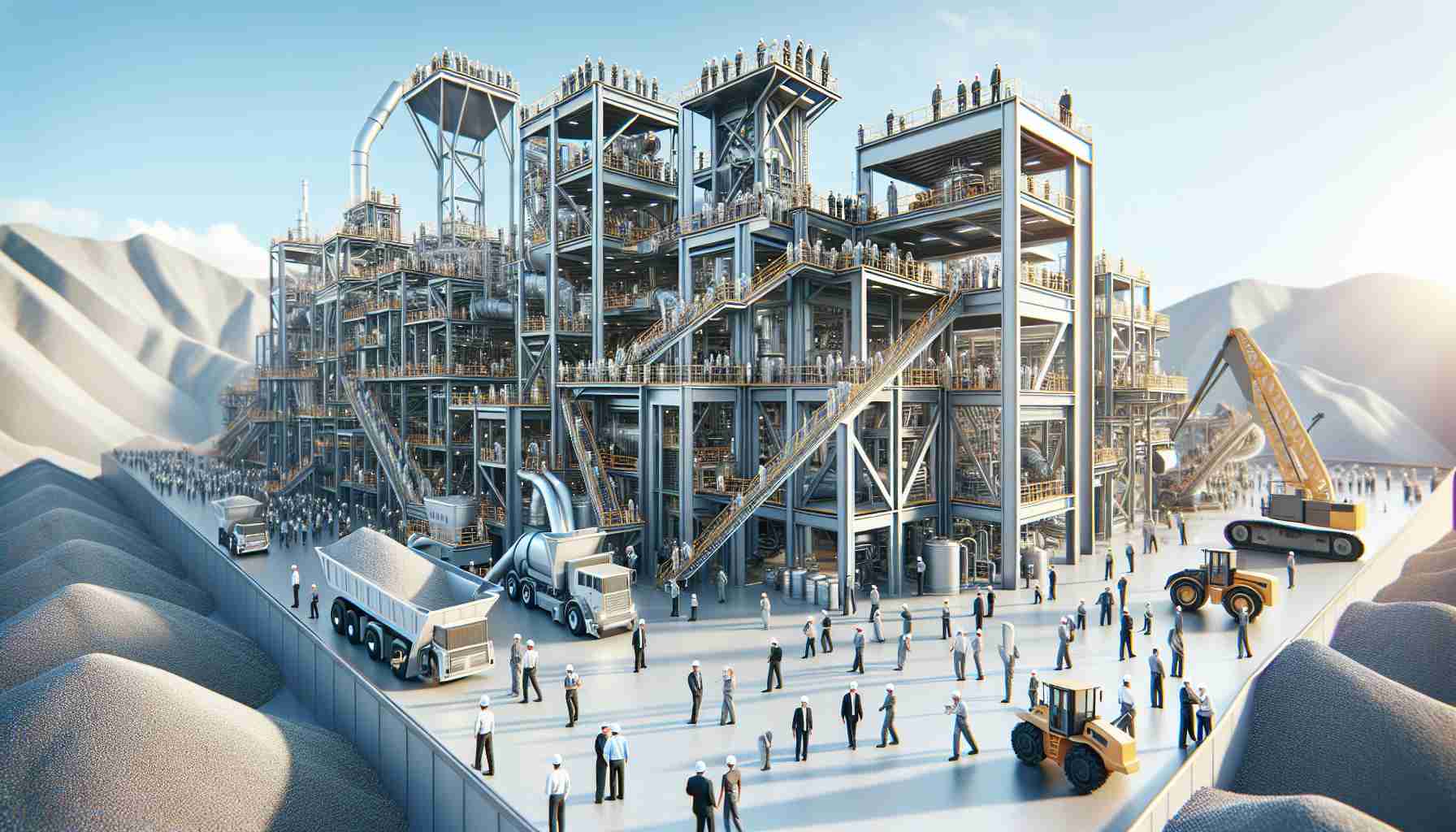

A cutting-edge breakthrough has been made in the extraction of lithium in North America, marking a significant step forward in the industry. The innovative process involves the utilization of specialized ion exchange beads that are smaller in size and possess a remarkably larger surface area compared to traditional beads, resulting in enhanced extraction efficiency. This pioneering technique has been met with great success during testing stages and pilot projects, demonstrating consistent lithium extraction from brines.

Leading the charge in this transformation is North America’s Volt Lithium, poised to become one of the first commercial producers of lithium sourced from oilfield brine. President & CEO, Alex Wylie, expressed excitement over the production of battery-grade lithium carbonate, which represents a milestone achievement for the company. The advanced Direct Lithium Extraction (DLE) approach adopted by Volt involves a meticulous two-stage process designed to ensure the removal of contaminants from brine before the extraction process commences.

With ambitious plans to scale up commercial production to 100,000 barrels per day by 2025, Volt Lithium’s success story continues to attract interest from potential offtake partners and investors alike. The company’s dedication to innovation and sustainability sets a new standard in lithium extraction techniques, laying the foundation for a greener future in the energy sector.

New Developments in Lithium Extraction Techniques in North America

In the realm of lithium extraction in North America, recent advancements have been reshaping the landscape of the industry, bringing to light some crucial yet lesser-known facts that are integral to understanding the revolutionizing processes at play.

One key question arising from these developments is: What specific improvements have been achieved in the ongoing quest to enhance lithium extraction techniques in the region? The answer lies in the utilization of cutting-edge nanofiltration technology, which allows for higher selectivity in capturing lithium ions while minimizing the presence of impurities in the extracted brines.

Moreover, a significant challenge that has come to the forefront is the environmental impact associated with large-scale lithium extraction operations. As demand for lithium continues to surge due to its pivotal role in battery production for electric vehicles and renewable energy storage, the need to address concerns regarding water usage, land disturbance, and potential ecosystem disruptions has become paramount.

On the flip side, one of the key advantages of the latest extraction methodologies is their ability to optimize resource utilization and reduce overall processing times, thereby streamlining the production of high-purity lithium compounds essential for various industrial applications. Furthermore, advancements in lithium extraction techniques offer the potential to boost domestic supply chains and lessen the dependence on imported lithium resources.

Despite the promising prospects offered by these innovative approaches, a notable controversy surrounds the socio-economic impacts of large-scale lithium extraction projects on local communities and indigenous populations. Balancing the economic benefits of lithium mining with social and environmental considerations remains a critical issue that industry stakeholders must address through transparent dialogue and sustainable practices.

For those seeking further insights into the evolving landscape of lithium extraction techniques in North America, exploring reputable sources such as ResearchGate can provide in-depth research papers and reports from experts in the field. Stay tuned as the journey towards a more sustainable and efficient lithium extraction process continues to unfold in the region.