- Xaar’s inkjet technology is revolutionizing battery manufacturing for electric vehicles.

- Innovative printheads like Xaar eX and Nitrox eX are enhancing battery production efficiency and safety.

- Collaborations with industry leaders aim to develop advanced coatings for increased battery durability.

- The technology significantly reduces production waste while improving coating quality.

- Xaar is contributing to a circular economy by extending battery lifespans and reducing replacements.

- The shift towards electrification highlights Xaar’s role in promoting sustainable energy solutions.

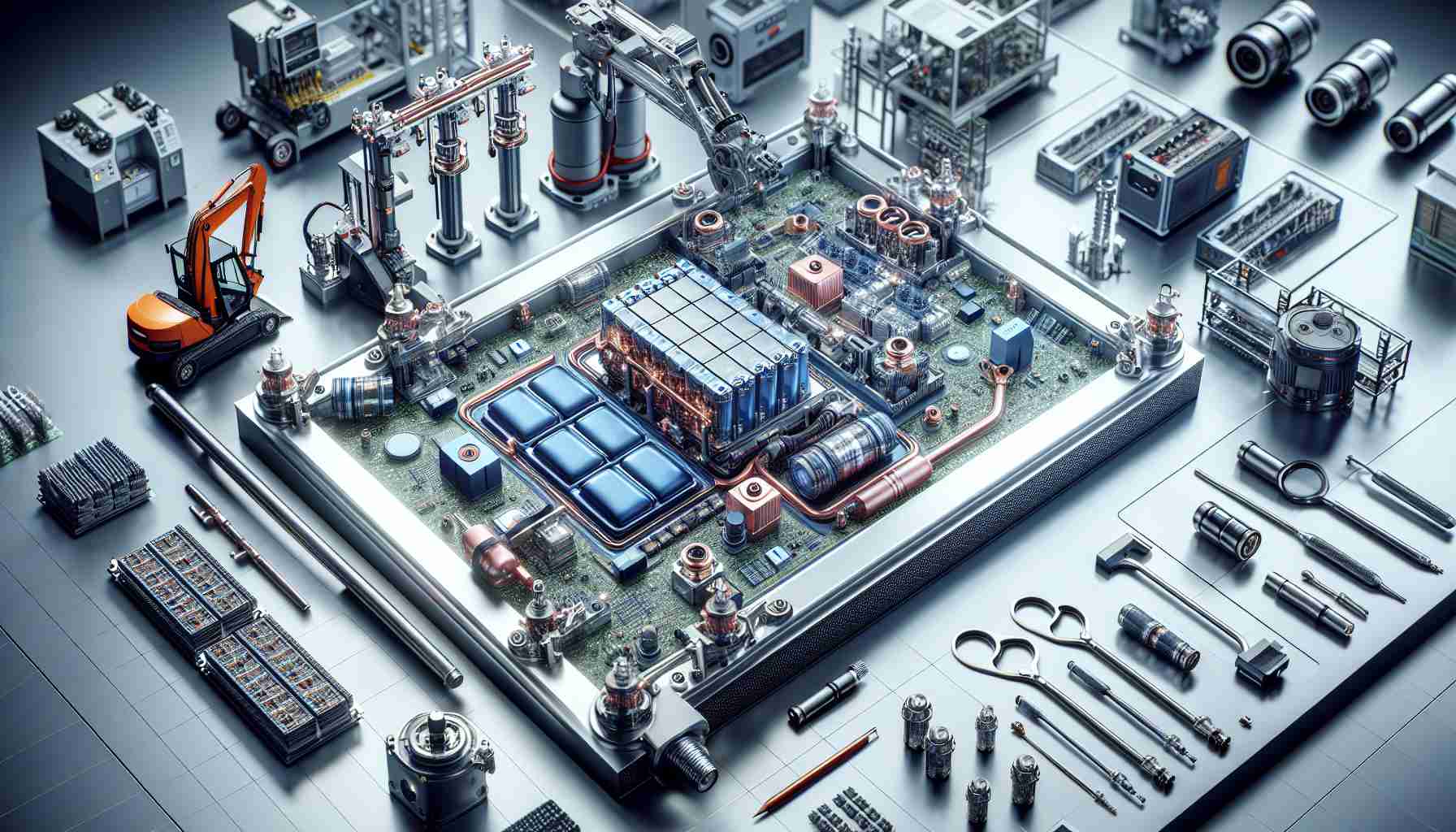

In a world racing towards sustainable energy solutions, Xaar is stepping up to revolutionize battery manufacturing. Using its groundbreaking inkjet technology, Xaar is transforming how electric vehicle (EV) batteries are produced, making them safer, more efficient, and environmentally friendly. With innovative printheads like the Xaar eX and Nitrox eX, traditional coating methods are being replaced, heralding a new era in the electric vehicle market.

As the demand for high-performance batteries soars, Xaar is forging powerful partnerships with industry leaders to develop advanced coatings that enhance durability. Just imagine batteries that resist overheating while delivering optimal performance—it’s no longer just a dream. Xaar’s technology slashes production waste while ensuring top-quality coatings, leading to longer-lasting batteries.

The shift towards electrification is clearer than ever, and with Xaar at the forefront, the implications are enormous. By significantly improving battery lifespans and reducing the need for frequent replacements, Xaar is not only boosting efficiency but also promoting a circular economy within the industry.

As we accelerate into the future of clean energy and electric vehicles, Xaar’s innovative spirit is paving the way for a safer ride. Get ready to witness the electrifying advancements that will reshape your drive! Stay tuned for more updates on how Xaar is connecting innovation with sustainability in battery technology.

Revolutionizing Battery Production: Xaar’s Innovations in Sustainable Energy

In a world racing towards sustainable energy solutions, Xaar is taking significant strides in transforming battery manufacturing. Utilizing its pioneering inkjet technology, Xaar is redefining how electric vehicle (EV) batteries are produced, resulting in advancements that make them safer, more efficient, and environmentally friendly.

Overview of Xaar’s Innovations

Xaar’s revolutionary printing technologies, such as the Xaar eX and Nitrox eX, are now replacing traditional coating methods, ushering in a new era for the electric vehicle market. Here are some of the new, relevant, and true aspects of Xaar’s impact in this field:

– Production Efficiency: By utilizing inkjet technology, Xaar significantly reduces production waste, ensuring higher quality coatings and consistently superior battery performance.

– Enhanced Battery Durability: Through collaboration with industry leaders, Xaar is developing advanced coatings designed to resist overheating while maintaining optimal performance levels, which enhances battery longevity.

– Market Trends and Sustainability: With an increased focus on sustainability, Xaar’s technology aligns with global trends toward electrification and a circular economy, promoting more sustainable practices across the battery lifecycle.

Key Features and Specifications

– Innovative Printheads: The Xaar eX and Nitrox eX employ advanced inkjet technology, allowing for precise and efficient application of battery coatings.

– Environmentally Friendly Production: The shift to inkjet technology reduces the environmental footprint of battery production, promoting sustainability.

– High Temperature Resistance: The new coatings being developed can withstand higher temperatures, reducing the risk of battery failure.

Pros and Cons

| Pros | Cons |

|————————————————|——————————————–|

| Improved battery efficiency and lifespan | Initial investment in new technology can be high |

| Reduced production waste | Transition period for manufacturers adopting the new technology |

| Enhanced safety features | Requires retraining of workforce for new processes |

Frequently Asked Questions

1. How does Xaar’s inkjet technology improve battery manufacturing?

Xaar’s inkjet technology allows for precise application of coatings, reducing waste and ensuring uniform coverage. This enhances battery performance and longevity while also being more environmentally sustainable.

2. What impact will Xaar’s advancements have on the sustainability of electric vehicles?

By improving battery lifespans and reducing the need for replacements, Xaar’s innovations promote a circular economy. This leads to less waste and a smaller environmental impact associated with battery production and disposal.

3. What partnerships is Xaar forming to enhance its technology?

Xaar is collaborating with several industry leaders to develop advanced coatings that improve durability and performance. These partnerships aim to integrate cutting-edge materials and technologies into the battery production process.

Insights and Market Forecasts

The electric vehicle market is expected to grow exponentially in the coming years, with a projected increase in demand for high-performance batteries. Xaar’s innovations position it well to capture a significant share of this market, especially as sustainability becomes a major focus for manufacturers and consumers alike.

Trends and Predictions

– Increased Use of Inkjet in Battery Production: As the technology matures, expect more manufacturers to adopt inkjet methods for efficiency and sustainability.

– Growth in Electric Vehicle Adoption: With improvements in battery technology, the adoption of electric vehicles is likely to rise, influenced by performance enhancements and environmental considerations.

For more insights on innovative battery technologies, visit Xaar.